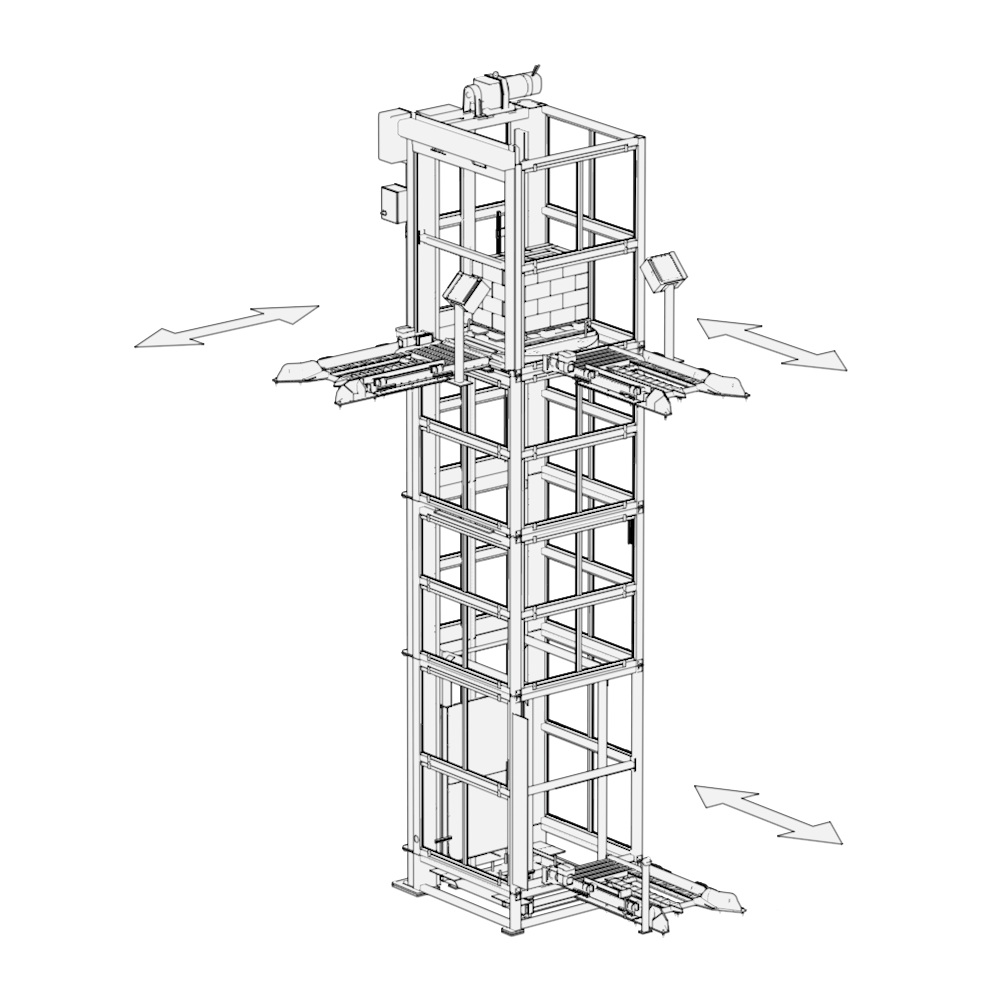

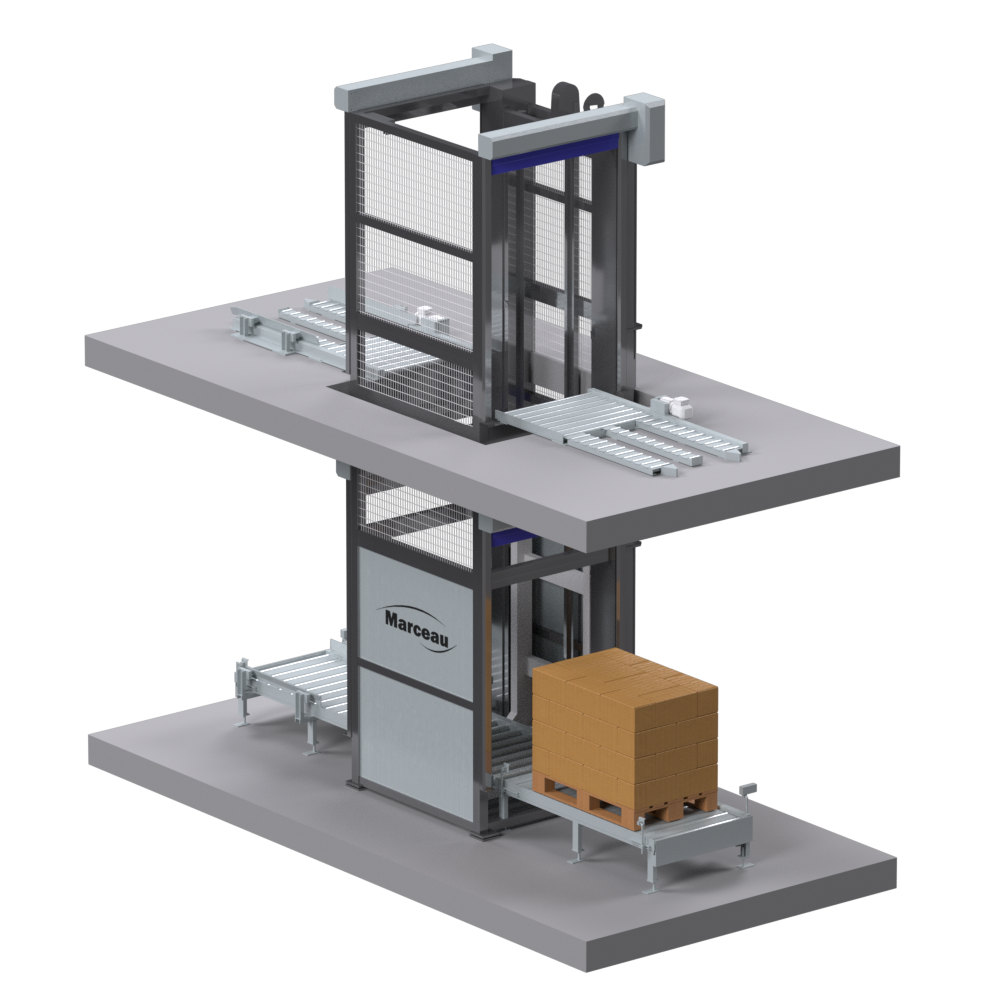

Increase productivity and safety with the Montepal® system

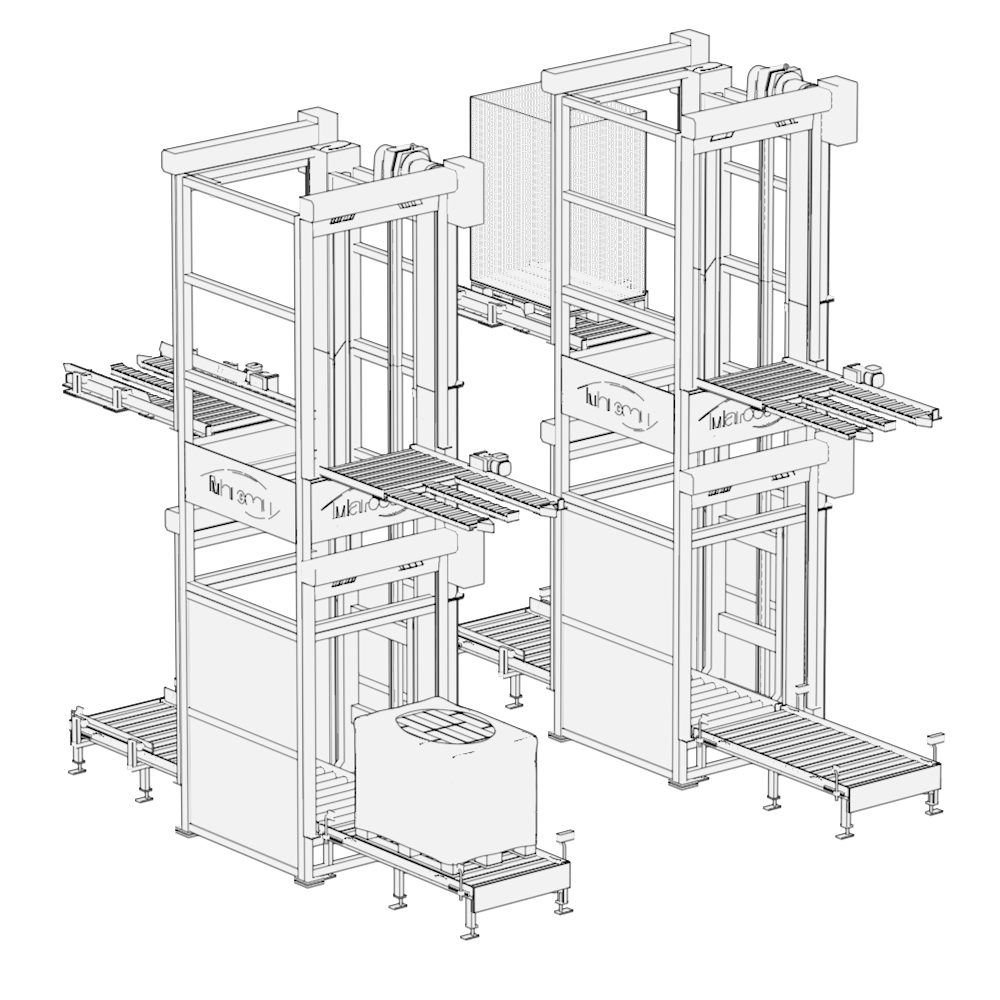

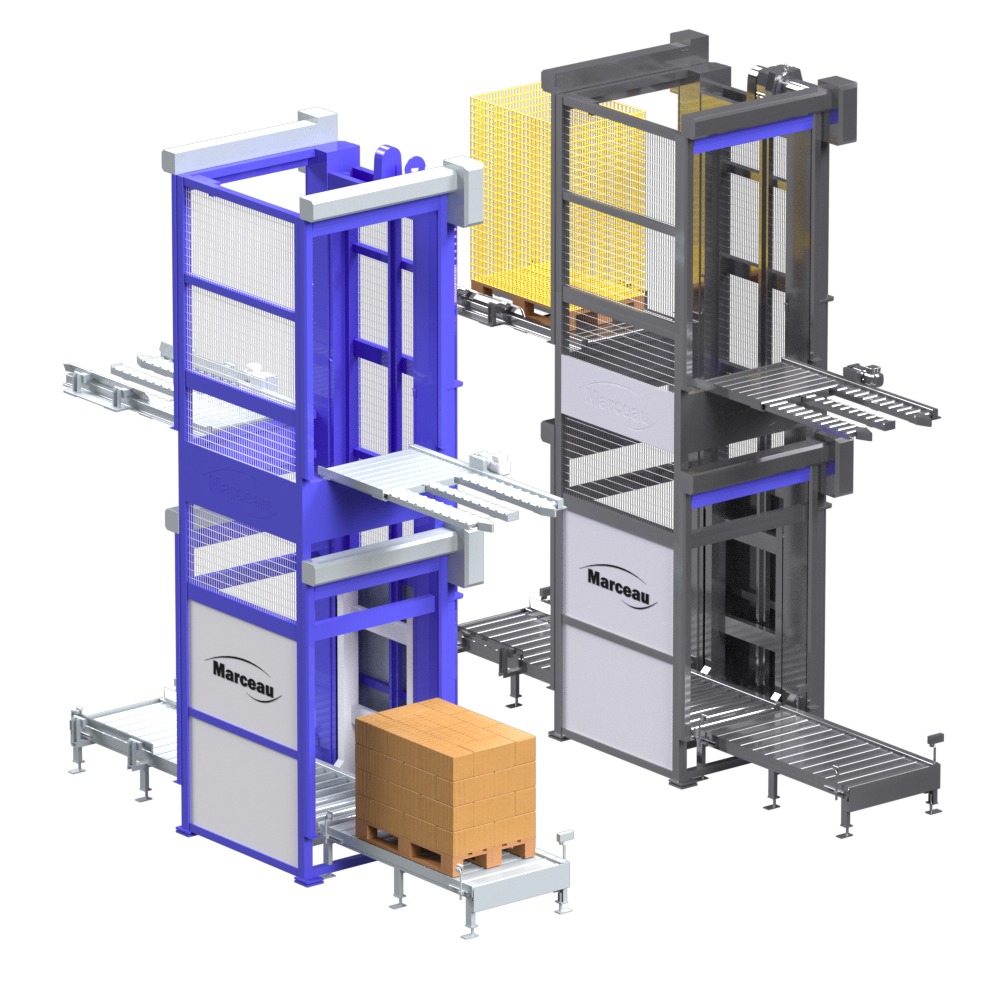

Designed and manufactured to suit your environment and requirements.

-

WHAT TYPES OF LOADS CAN BE TRANSPORTED?

Our Montepal elevator is designed to meet your needs and is perfectly adapted to these types of products:

- Pallets

- Wire cages

- Rolls

- Box pallets

- Big Bags

- Others- WHAT IS THE MAXIMUM LOAD?

Maximum load up to 2,000 kg.

- WHAT IS THE CADENCE?

Maximum output up to 150 pallets/hour.

- CAN THE SYSTEM BE USED UP AND DOWN?

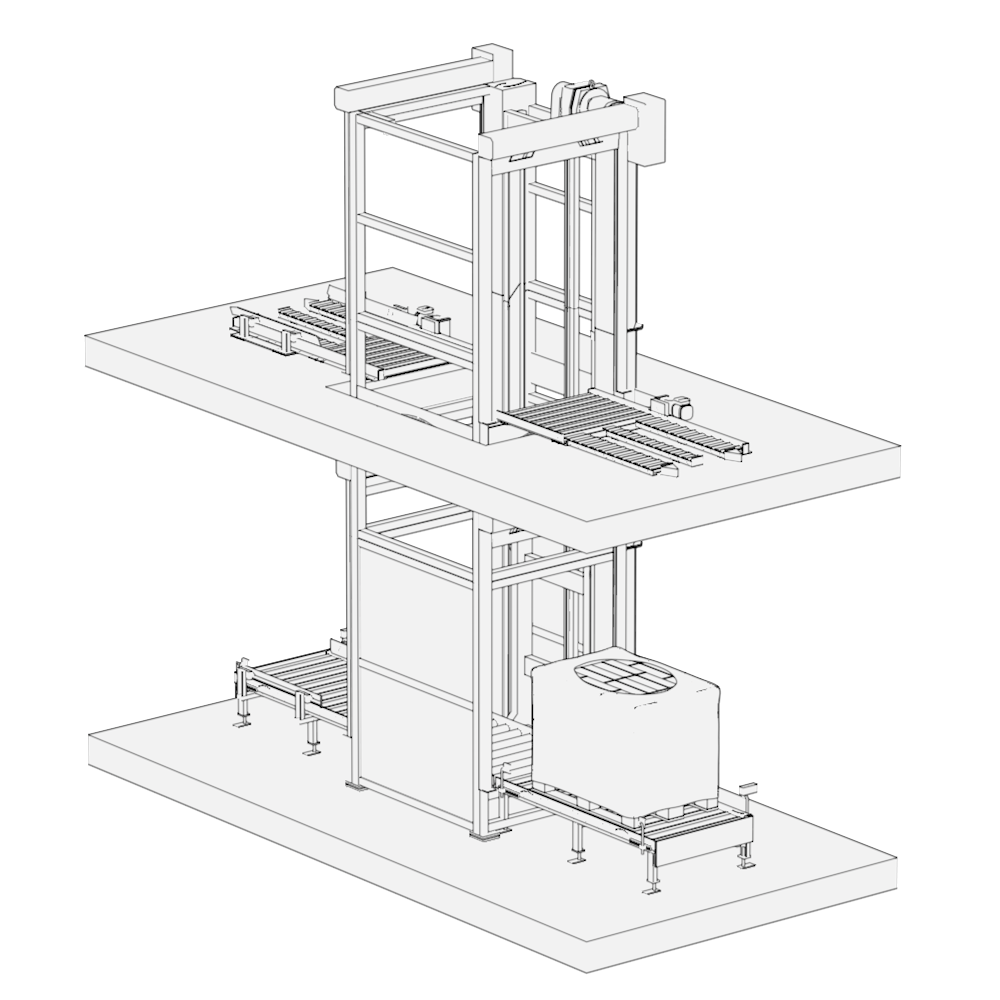

Yes, the MONTEPAL® has several functions:

- Direction of climb only

- Direction of descent only

- Direction of climb and descent

- CAN THE SYSTEM BE INTEGRATED INTO AN EXISTING CONVEYOR LINE?

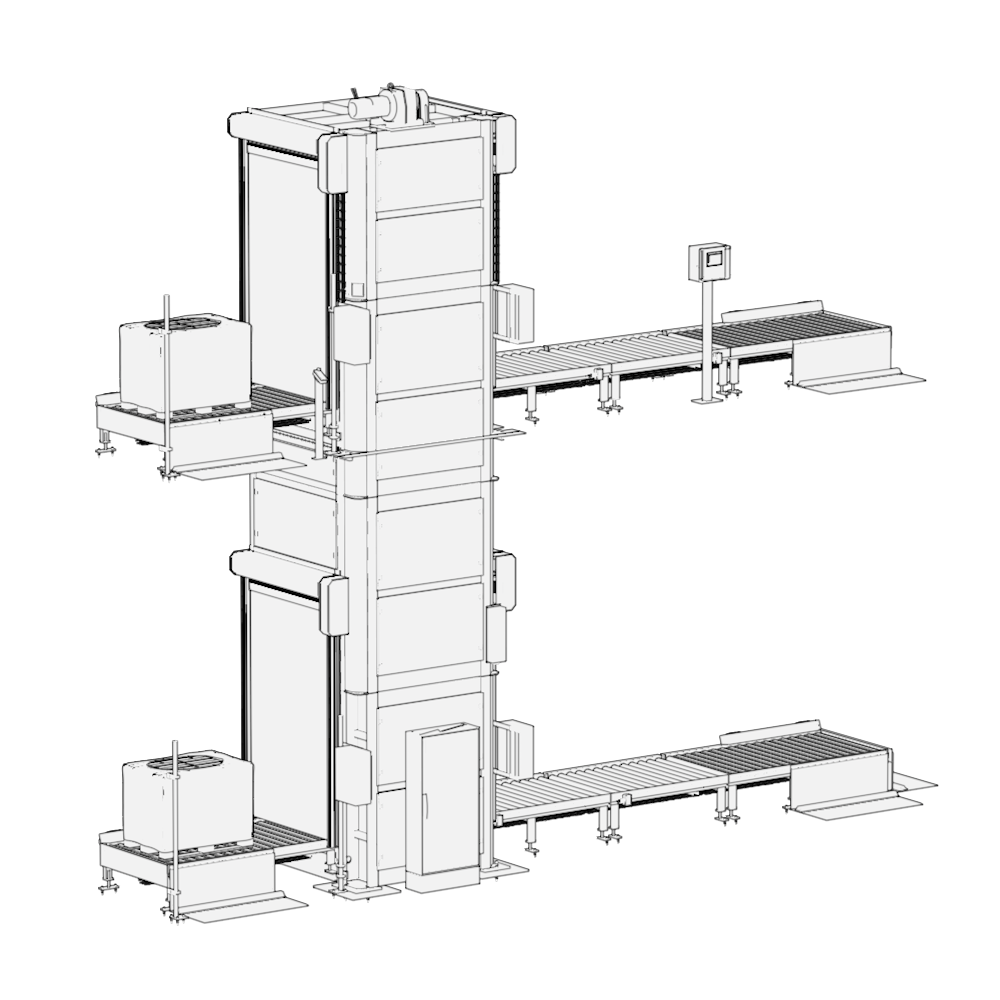

Yes, the pallet elevator can be stand-alone or integrated into a conveyor line.

- WHAT FINISHES ARE POSSIBLE?

- Painted steel

- Hot-dip galvanized steel

- Stainless steel

- WHAT INTERFACES ARE POSSIBLE?

- Forklift trucks

- AGV or AMR integrated into an automatic conveyor line

- Stacker

- Pallet truck

- Automatic conveyor line - WHAT IS THE MAXIMUM LOAD?

Our key benefits

Options available to suit all your needs and constraints.

APPLICATION

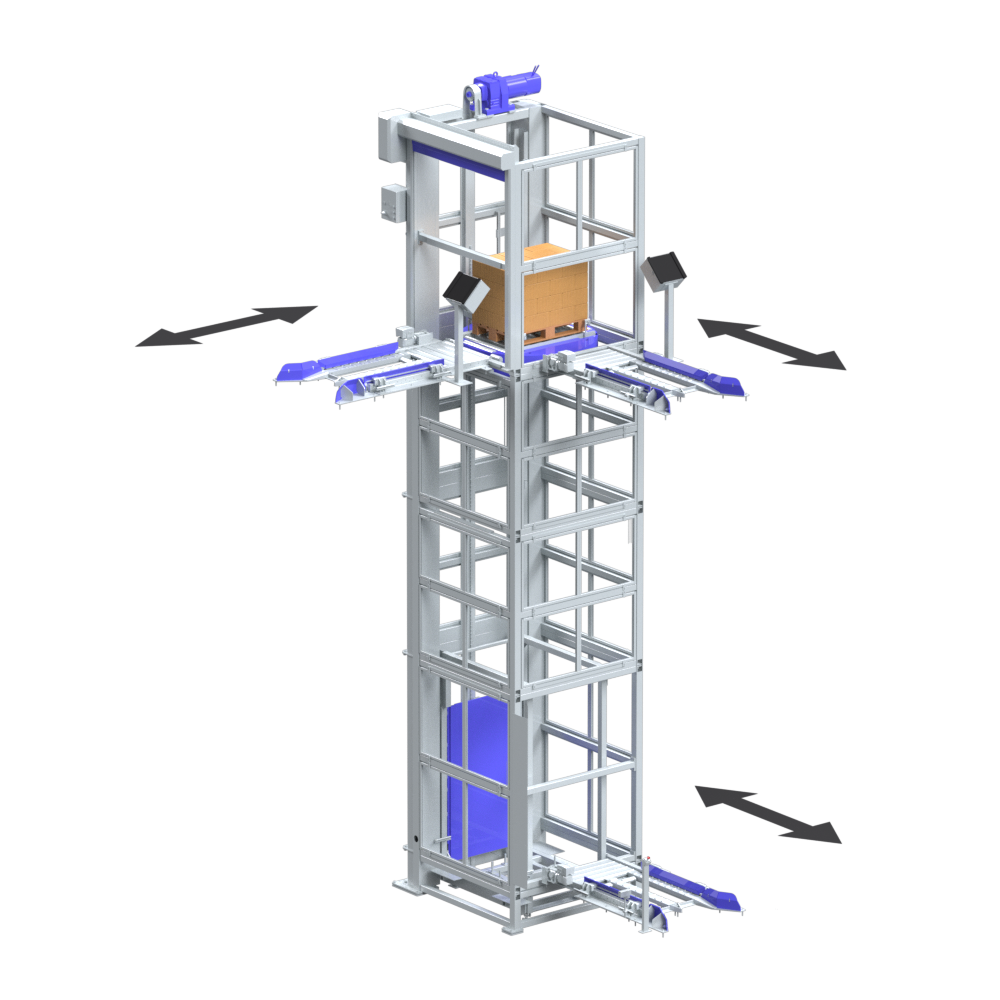

The MONTEPAL® pallet elevator is designed to transport your palletized loads safely between the different levels of your buildings. It can also be used for inter-building links.

MACHINE RANGE

Designed to transport your palletized loads automatically (PLC-controlled), the Montepal® pallet elevator is not a freight elevator or an elevator, and is classified as a machine (no mandatory periodic inspection).

FOR ALL ENVIRONMENTS

The various manufacturing options enable the MONTEPAL® pallet elevator to adapt to all working environments and to be used in all sectors of activity, including agri-food, logistics, chemicals, pharmaceuticals, cosmetics and retail.

SELF-SUPPORTING FRAME

The Montepal® pallet elevator consists of a self-supporting welded frame and requires no civil engineering (no ground pit).

Our Achievements

For over 40 years, the company MARCEAU has specialized in the design of continuous handling systems.

Our customers references

![Image d'un élévateur Montepal sur ...étages pour le transport de ... [secteur Agro]](../assets/img/refs/img-1.jpg)

![Image d'un élévateur Montepal sur ...étages pour le transport de ... [secteur Agro]](../assets/img/refs/img-2.jpg)

![Image d'un élévateur Montepal sur ...étages pour le transport de ... [secteur Agro]](../assets/img/refs/img-3.jpg)

![Image d'un élévateur Montepal sur ...étages pour le transport de ... [secteur Agro]](../assets/img/refs/img-4.jpg)

![Image d'un élévateur Montepal sur ...étages pour le transport de ... [secteur Agro]](../assets/img/refs/img-5.jpg)

![Image d'un élévateur Montepal sur ...étages pour le transport de ... [secteur Agro]](../assets/img/refs/img-6.jpg)